„From a thought to a functional result.“

PRECISION-EFFICIENCY-QUALITY

More than 20 years of experience in the automotive industry.

What can you expect from us?

Manual assembly

Thanks to the expertise and precise skills of our operators, we are able to ensure high-quality manual assembly of even the most complex components. The portfolio mainly includes the assembly of plastic connectors, where attention to detail and care are the key.

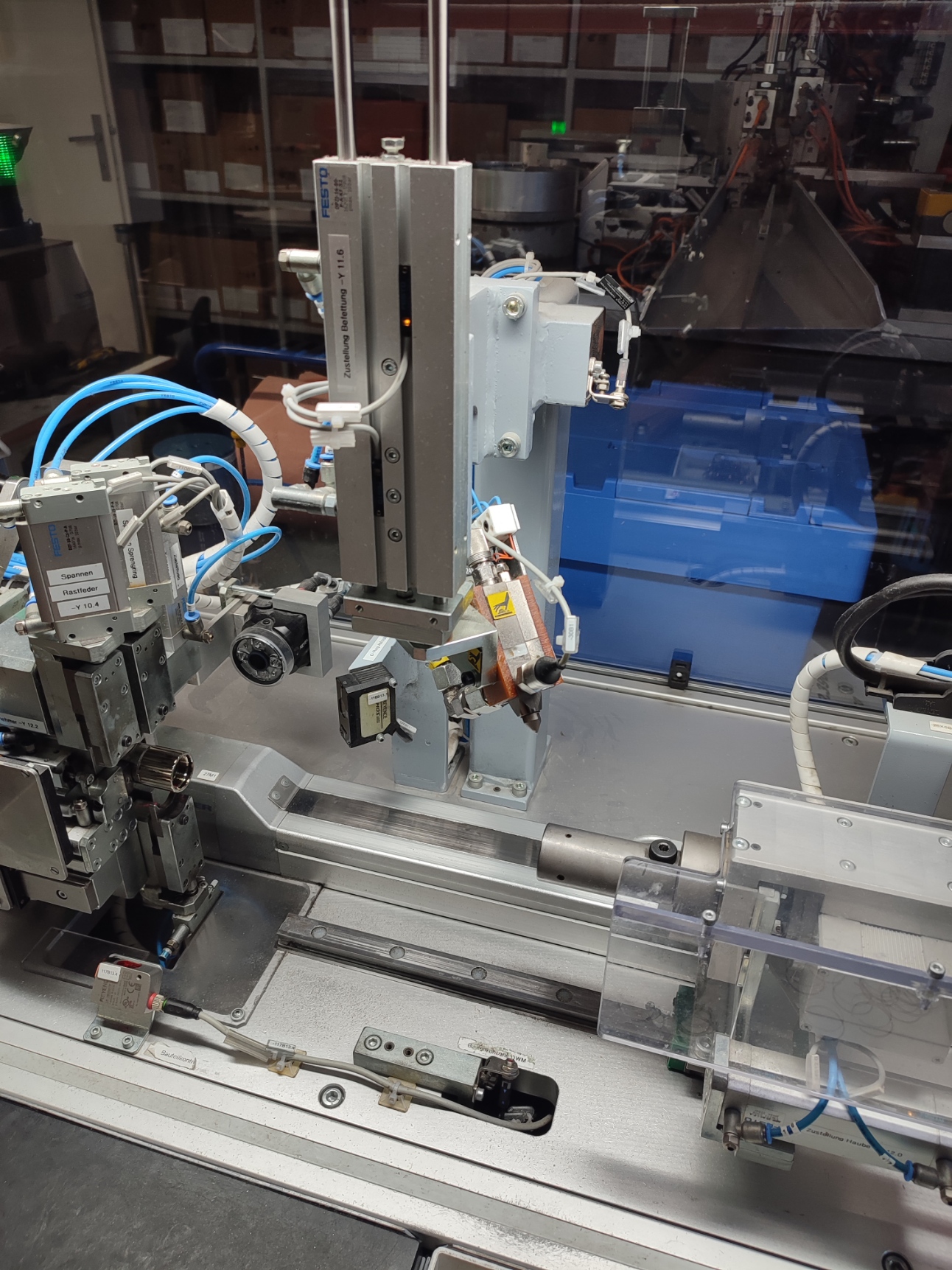

Assembly with tools

To ensure maximum repeatability and consistency of the process, we use presses or advanced fixtures for assembly. These tools eliminate the risk of error and ensure that each product is assembled exactly to specification.

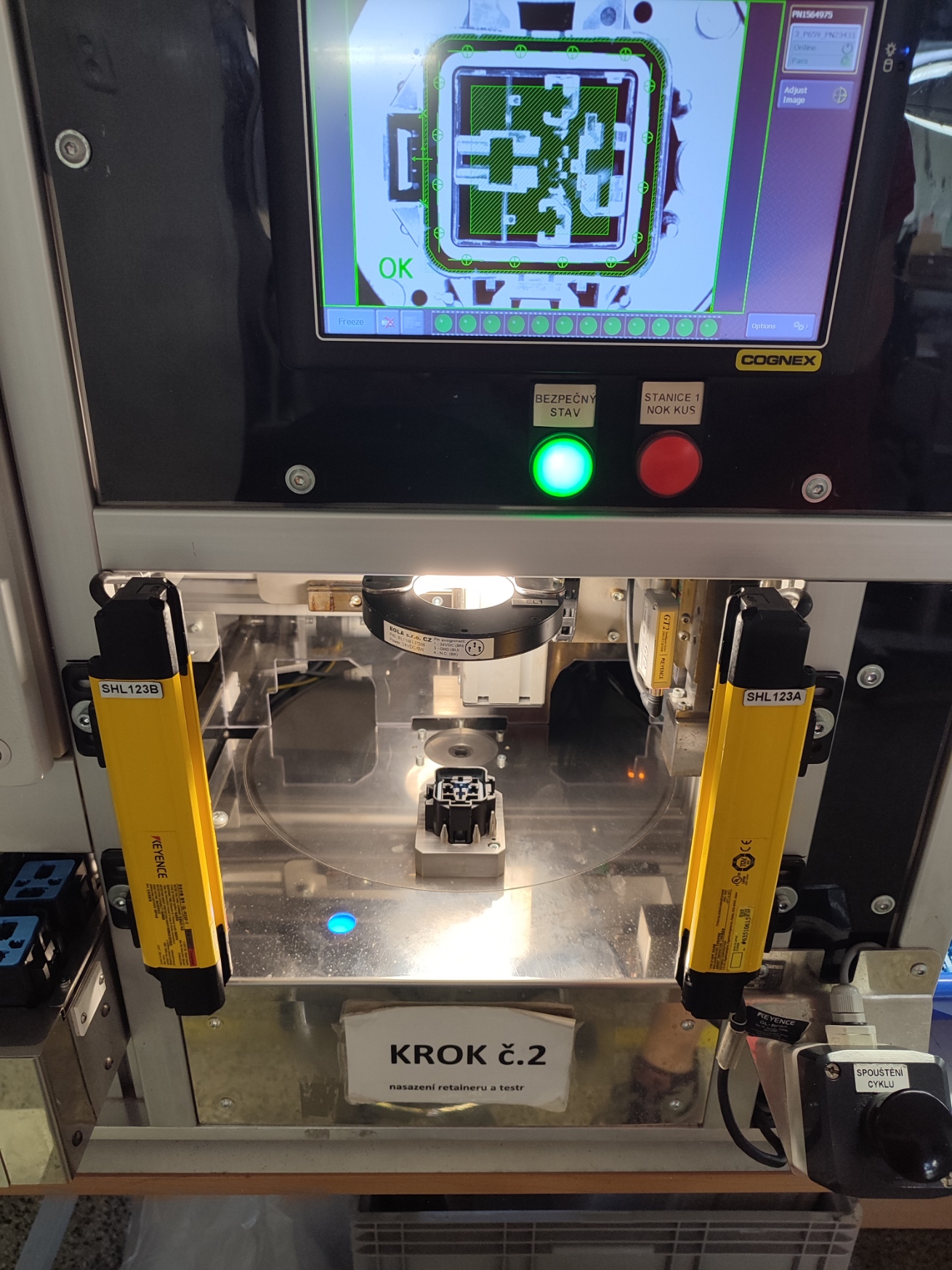

Semi-automatic assembly

By combining human skill and machine power, we achieve the optimal balance of efficiency and quality in semi-automatic assembly. This process allows us to process higher production volumes in less time without compromising our standards.

Metrology

We can take up to 99 measurements in just 3 seconds, with an accuracy of 0.005 mm. This process allows us to instantly verify the quality of even the most complex parts. It is a guarantee of reliability and peace of mind.

Research and development

We have experience in the technical and design phases of developing new tools and assembly processes. We offer complete support – from the initial idea to the perfect final implementation. The result is an efficient and reliable assembly that meets even the most demanding requirements.

Certification

ISO 9001 since 2004

ISO 14001 since 2004

IATF 16949:2016 - only applied since 2008

UL, VDE since 2023